Polyacrylic fiber Description:

Acrylic fibers are synthetic fibers that range from a polymer (polyacrylonitrile) with an average molecular weight of about 10000, to about 1900 monomers per unit. The polymer must have at least 85% acrylonitrile monomers. Common comorbidities are vinyl acetate or methyl acrylate.

Table of Contents

Modacrylic is a modified acrylic fiber that contains a minimum of 35% and a maximum of 85% acrylonitrile monomer.

The common denominator used in Modacrylic is vinyl chloride, vinylidene chloride, or vinyl bromide fiber flame. Modacrylic end-uses include fax fur, wigs, hair extensions, and protective clothing.

Polyacrylic Fiber Production:

Polymers are formed by free-radical polymerization in aqueous suspensions. Fiber is produced by dissolving polymers in solvents such as N, N-dimethylformamide (DMF), or aqueous sodium thiocyanate, which is metered through a multi-hole spin rate and frozen in the aqueous solution of the same solvent (wet spinning).

Dry spinning) Solvent evaporation inflow. Complete washing, stretching, drying, and crimping processing. Acrylic fibers typically range from 0.9 to 15 cut staples or from 500,000 to 1 million filament tao.

Polyacrylic fiber Used in textiles:

Acrylic is light in weight, soft and warm, and feels like wool. It can mimic other fibers, such as cotton cut into short main tools. Some come out in the form of acrylic paints or dyes; The other is extruded into “Icrew”, otherwise known as “natural,” “raw white” or “non-white”. Pigmented fibers have the greatest scarcity. Its fibers are highly elastic compared to both other synthetic and natural fibers.

Some Polyacrylic fibers are used as a less expensive alternative than cashmere, due to the similar feel of the materials. Some acrylic fabrics can easily bend or peel, although there are low-peeling variants. Acrylic paint is well-absorbed, washable, and usually hypoallergenic. End-uses include socks, hats, gloves, scarves, sweaters, upholstery, and ankles. The acrylic mesh can also be used to make fur and various woven fabrics.

Polyvinyl Description:

A synthetic fiber made from vinyl polyvinyl chloride. In a few countries other than the United States, vinyl fiber is identified as polyvinyl chloride fiber. It can tie non-woven fibers and fabrics. It was invented in 1939.

It has the same health problems as chlorinated polymers. In the past, Vionon was used as an alternative to plant-based filters in tea bags.

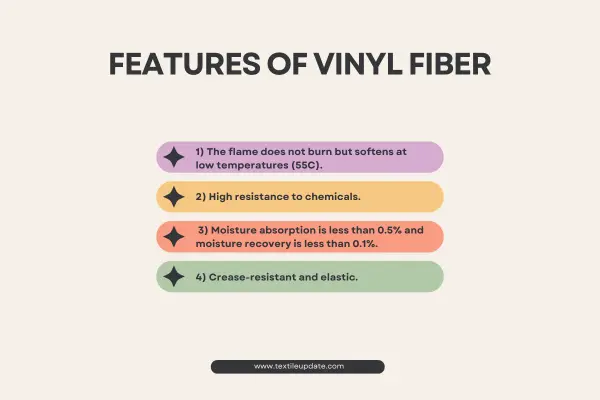

Features of vinyl fiber:

- 1) The flame does not burn but softens at low temperatures (55C).

- 2) High resistance to chemicals.

- 3) Moisture absorption is less than 0.5% and moisture recovery is less than 0.1%.

- 4) Crease-resistant and elastic.

Production:

The U.S. Federal Trade Commission’s definition of vinyl fiber is “a manufactured fiber where the fiber is made of a synthetic polymer of linen chain made up of at least 85 percent by weight of vinyl chloride units (—CH2 – CHCl—)”.

Use of Major Vinyl Fiber: It is used in industry as a bonding agent for non-oven fabric production.

You may also like to read: