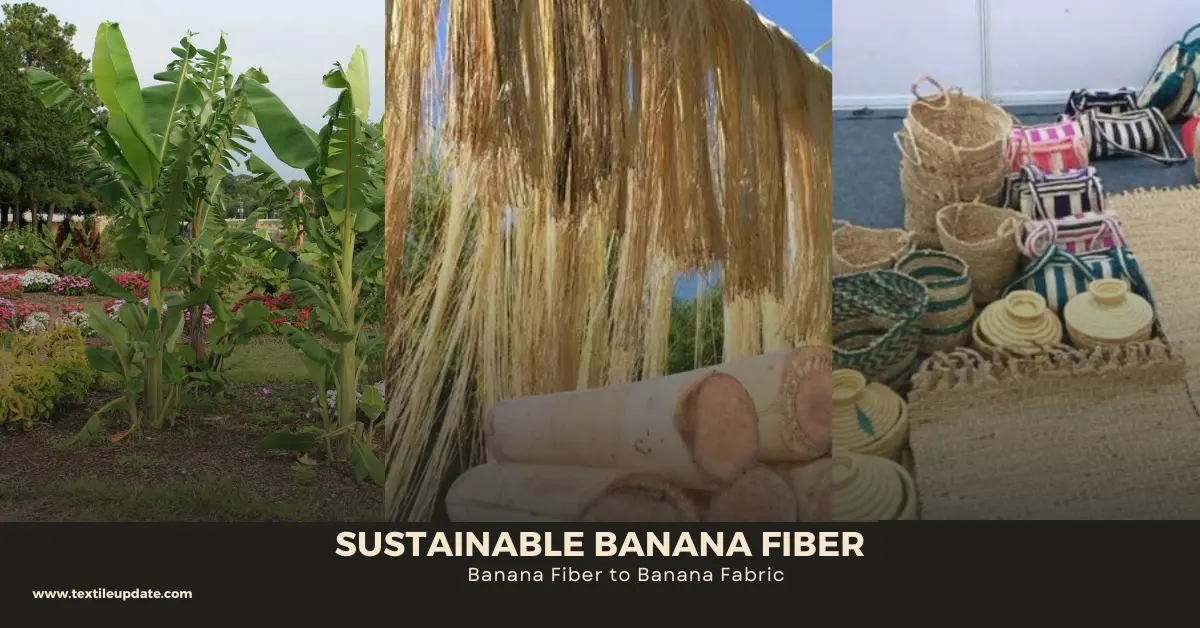

MUSA SPP is the scientific name of the Banana Plant. Banana is a nutritious fruit and consists of a lot of vitamins. One time when we collected the banana & banana fiber from the plant and the waste of the plant was not working for any purpose. Some other children playing with the plant of fallen banana. At the time stink of the banana plants and the environment was reprehensible.

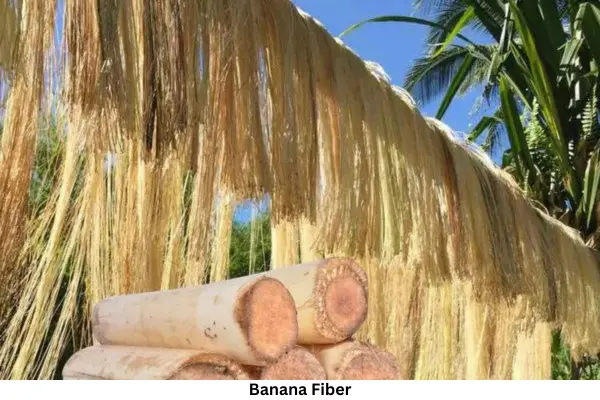

No use of commercial Bangladesh. Some other scientists research how to use the waste of banana plants. And how to commercially use how to manufacture the yarn and how to convert the product. They spend time researching the waste of banana plants and finally find a positive result. They have collected shoots from the waste of plants. And these shoots are given by electric machine but this machine is so costly.

Bangladeshi factory making the machine and per machine price up to 1 lack 30 thousand Tk. And finally got the yarn. The first step of this yarn is Chippy and not dried. So the yarn has dried the temperature and the faulty yarn. When got the best yarn to make the many other things. For example bags, Handicrafts, Paper, mats, diapers, napkins, filter paper, banknotes, ropes, tablecloths, tea bags, etc.

Banana Plant is used for organic fertilizer. This yarn is not so costly as a result of to use for many purposes. Banana fiber absorbency is so high and consequently used the medical purposes for example bandages. Banana plants create employment sectors for a lot of unemployed men & women. When we arrange arrangement well training process at a certain this yarn exported the many other countries. And it creates earning sources for Bangladesh. It’s a sustainable fiber and also sustainable. Banana fiber to make baby products for example baby toys. The green banana paper uses the banana paper to make the wallets and weaves the raw banana fibers to create hand-woven banana fabric items such as laptop bags and purses.

The banana fiber is used in handmade baskets or baskets. It’s not so heavy so easily carried from one place to another place. When this product is more fashionable to the customer more want it because it’s not so high priced. It’s used in the office, market and many other places. Hence this product is sustainable and lasts many other days. One more thing it’s washable and its absorbance capacity is high. And when it’s not to use this product to mix the soil. As a result, remove the stink from the environment.

Banana fiber can also be used in marine rope since this fiber has good resistance to seawater. Banana fiber uses yoga mats, mobile phone covers, door mates, and curtains, and is also comfortable to wear. Summer seasons are more used to making dresses the banana fiber. Coarse woven fabrics for example hessian, sacks, twines, canvas and screens, kit bags, tool bags, luggage covers, and rags etc.

Properties of banana Fiber:

- It’s a highly strong fiber.

- This fiber has a smaller elongation.

- Abaca fiber has a strong absorption quality.

- It’s lightweight fiber.

- Banana fiber has physical & chemical Characteristics.

- It’s an eco-friendly natural fiber.

- It has tenacity, moisture regain, density, lignin, and many other properties.

- Abaca fiber is also recyclable.

- It’s bio-degradable and has no negative side effects on the environment

Banana fiber also known as MUSA fiber is one of the world’s strongest natural fibers. Banana fiber more sustainable alternative to silk. Banana fiber is becoming known in the textile world.

Prosenjit Paul

Shahid Abdur Rab Serniabt Textile Engineering College, Barishal

prosenjittex7@gmail.com

May you like to read: